A simple design for small pouches with high capacity is possible with our Mini vertical form fill and seal machines. Up to 15cm bag width and 25cm bag, length flexibility covers mostly needed packaging demands as well as to fill 1kg of granule products maximum.

User-friendly electromechanical design and less footprint space-saving dimensions (nearly 1x2mt) bring high efficiency for your production with a very low investment.

Volumetric filler: Servo driven volumetric filling technology reduces downtime of adjusting weight changes and keep the capacity same up to 45 bags per minute from 50gr. to 1000gr. The volumetric filler is one of the most common filling technology in vertical form fill & seal packaging machine industry. What makes Mentpack packaging machines volumetric fillers the best is easy to use mechanical design, easily adoptable on Mini VFFS packaging machines and very low downtime. Because of the above reasons, our Mini VFFS volumetric filler is the best choice and great value for your investment.

Multihead weigher: Mini VFFS packaging machine equipped with Multihead weigher is giving the best accuracy for any type of granular product packaging. Multihead weighers are generally needed to weight and fill products that can be broken easily as well as products which are needed to count by weight.

Mini vertical form fill seal packaging machine is designed to save from footprint space and energy consumption. Projects that don’t need bigger than 15x25cm pouches up to 40-45 cycles per minute definitely should use our Mini VFFS packaging machine with a multi-head weigher.

Auger filler: A simple design for small pouches with high capacity is possible with our Mini vertical form fill and seal machines. Up to 15cm bag width and 25cm bag, length flexibility covers mostly needed packaging demands as well as to fill 1kg of granule products maximum.

User-friendly electromechanical design and less footprint space-saving dimensions (nearly 1x2mt) bring high efficiency for your production with a very low investment.

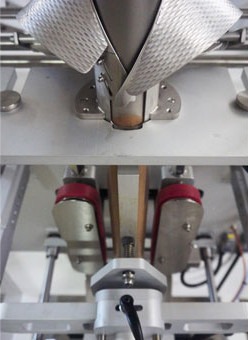

By making tailor-made agitator and auger screw manufacturing for each new project and standard servo driven auger screw motion gives the accuracy and capacity. Because of the above reasons, our Mini VFFS auger filler is the best choice and great value for your investment.

What are my advantages?

Servo driven transport belt

Vacuum transport belt

Servo driven horizontal sealer

Toolless vertical sealer adjustment

Toolless forming unit changeover

Toolless film changeover

Easy mark sensor adjustment

Motor-driven film tracking

The multi-program save and load function

Half opening silo for easy access and cleaning

Horizontal sealer pressure adjustment on HMI

Horizontal sealer distance adjustment on HMI

HMI mounted on swivel arm

User-friendly controls

Worldwide branded components

Spare parts catalogue

10 years plc & hmi software warranty

I/O test manual facility

Servo driven auger

Toolless changeover of auger screws

What can I pack?

Powder

Legumes

Liquid

How fast I am?

Powder: 25-35cycle

Legumes: 25-35cycle

Liquid: 15-25cycle

Technical details

Min. pack width : 80mm.

Max. pack width: 170mm.

Min. pack length: 10mm.

Max. pack length: 250mm.

Max. roll width : 550mm.

Energy consumption : 2,5 kW/h

Air pressure : 6-8 Bar

Air consumption : 250 liter/min.

Electricity : 3P+N+PE 220 VAC/110VAC

Weight: 750kg

* Above information can vary according to product type, project details and special occasions.