Horizontal sachet packaging machine is designed for flexibility in sachet dimensions and lower speed applications. Equipped with liquid filler for low to high viscous liquids such as oil, ketchup, sauces, mayonnaise, tomato paste, cream chocolate, cosmetic liquids, shampoo, CBD oil four sides sealed and/or three sides sealed sachet up to 40-50 cycles/minute speed maximum.

Furthermore, Mentpack has two different sachet packaging machine technology for low and high capacity needs. It’s with or without motion controlling technology on our horizontal sachet machines. 20 cycles/minute with die-cut punch. And 60 cylces/minute simplex. Both systems can work on our simplex or duplex machines.

We designed our liquid fillers for high speed and high accuracy filling without any drop or leaking problems. Servo driven piston pump with shut-off nozzles made with years of experience giving the best accuracy with zero-leaking. Thanks to long-lasting custom made gasket set in the actuator lasts up to 30 days at 3 shift running. Hence, easy gasket changes shorter the downtime of maintenance and CIP-Ready or CIP Cleaning options creates the efficiency for faster cleaning the companies which do not have CIP rooms.

Not only the premium brands that are selected in components, and also we like to make sure that our customers’ have uninterrupted manufacturing. So that, we supply free of charge remote connection technical support.

What are my advantages?

Widely opening sealers for easy cleaning

Unique extended life knife design

All motions fully synchronized with the speed thanks to the mechanical and software cams

Absence of sachet burning when stopped

Easy and precise sealing pressure adjustment

Bespoke sealing shapes

Bespoke sachet shapes

Vertical perforation

Tear notch as standard

User-friendly HMI controls

Worldwide branded components

Spare parts catalogue

10 years plc & hmi software warranty

I/O test manual facility

Servo motor liquid pump (0.01mm precision – 100mm/sec speed)

Maximum volume precision in a single piece actuator

Food grade quick release fittings

Teflon tubes

Actuator heating on double-jacket filling system

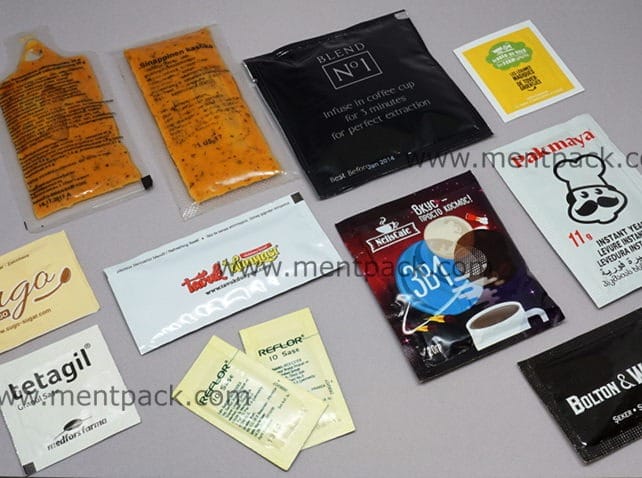

What can I pack?

Cosmetics

Ketchup

Mayonnaise

Mustard

Honey

Pomegranate sauce

Shampoo

Hair Gel

Gel Soap

Cream Chocolate

How fast I am?

20 pack/min (with die-cut)

60 pack/min

Technical details

Min. pack width : 10mm.

Max. pack width: 150mm.

Min. pack length: 10mm.

Max. pack length: 180mm.

Max. roll width : 1000mm.

Energy consumption : 1,5 kW/h

Air pressure : 6-8 Bar

Air consumption : 250 liter/min.

Electricity : 3P+N+PE 220 VAC/110VAC

Weight: 1000kg

* Above information can vary according to product type, project details and special occasions.