Stick pack vs Sachet machines? Nowadays, costumers need more diversity due to their different preferences and needs. Looking for more diverse choices in terms of functionality, quality and price of packaging machines for different products.

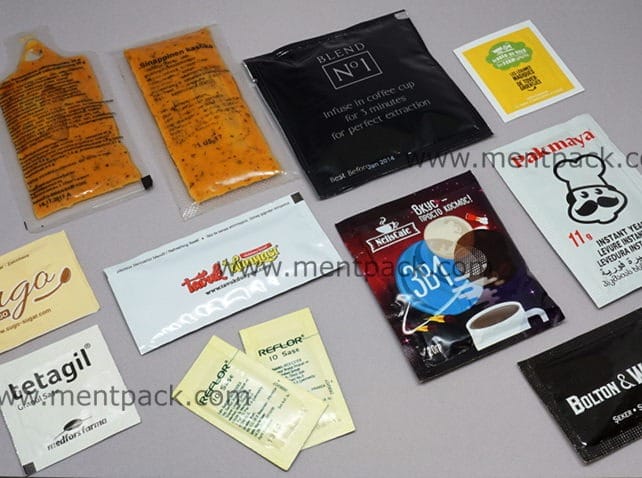

Buying single-use products such as sachet and stick became a tendency. Due to its practicality, easily transportable (the low weight and small size) and time-saving that makes daily life way easier. These two products create confusion in the buyer’s minds because they are so similar yet so different. Here we are at the first step of Stick pack vs Sachet comparison.

The shape of a stick pack is tubic, having a long, slender configuration. Typically, with a continuous side seam. A stick pack is at least four times longer than its width, with a common length ranging from 40 to 200 millimetres.

Sachets on the other hand are usually flat, and have a three or four-side-sealing.

To choose between sachet and stick packing machinery we usually depend on the type of product, what we use as flexible packing material, the quantity of the product in each pack, sealing method and desired production speed.

Stick packs and sachets are suitable for multi pack packaging, whether they contain pharmaceuticals, instant beverages, sugar, salt, spices or condiments.

The single-dose sachet packaging machines are horizontal or vertical packaging machines. It begins by cutting the film reel according to required dimensions, thus forming several rows

While The stick pack packaging is 3 sides heat-sealed film that is cut according to the number of tracks of the packaging machine. Such format, furthermore being aesthetically pleasing, allows notable ease of use and wrapping material saving.

Mentpack sachet and stick platform enable manufacturers to grow their market share and meet fast-changing market demands. Using Mentpack’s cutting-edge technologies, supported by proven market expertise, gives producers the flexibility, speed, simplicity, and reliability to meet cost-effective high-quality standards.