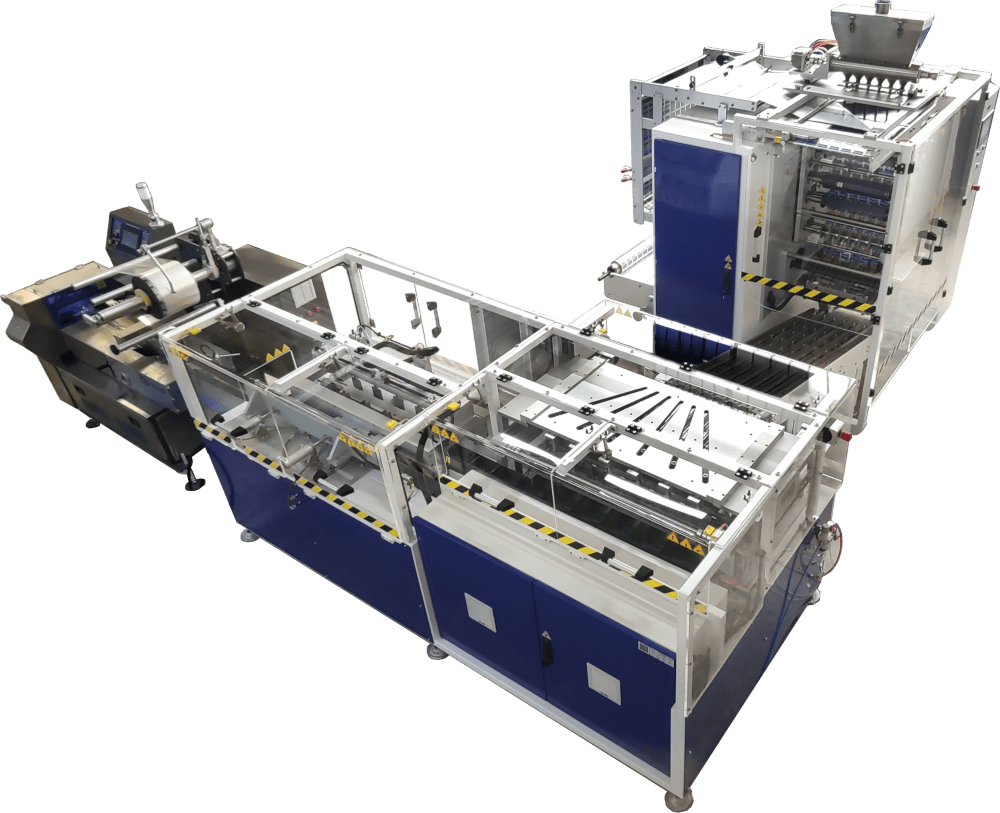

The sachet packaging line with flow wrapper packaging machine is basically linked line of sachet packaging machine as primary packaging machine, grouping/collating machine and flow wrapper (flow packing) as secondary packaging machine. Finally, the output of the line is primary and secondary packaging completed pouch packages.

Beyond your package shape and product, this packaging can be customized by Mentpack engineers to success your target primary and secondary packaging goal.

Convenience and efficiency are coming as a package with a sachet packaging machine line with secondary packaging machine. Since the first machine of Mentpack, we kept our focus on sachet packaging machines since 1996. When it comes to fixed package dimensions, sachet in pouch packaging line becomes the correct choice for mass manufacturing.

What are sachet packaging line advantages?

Centralized control unit

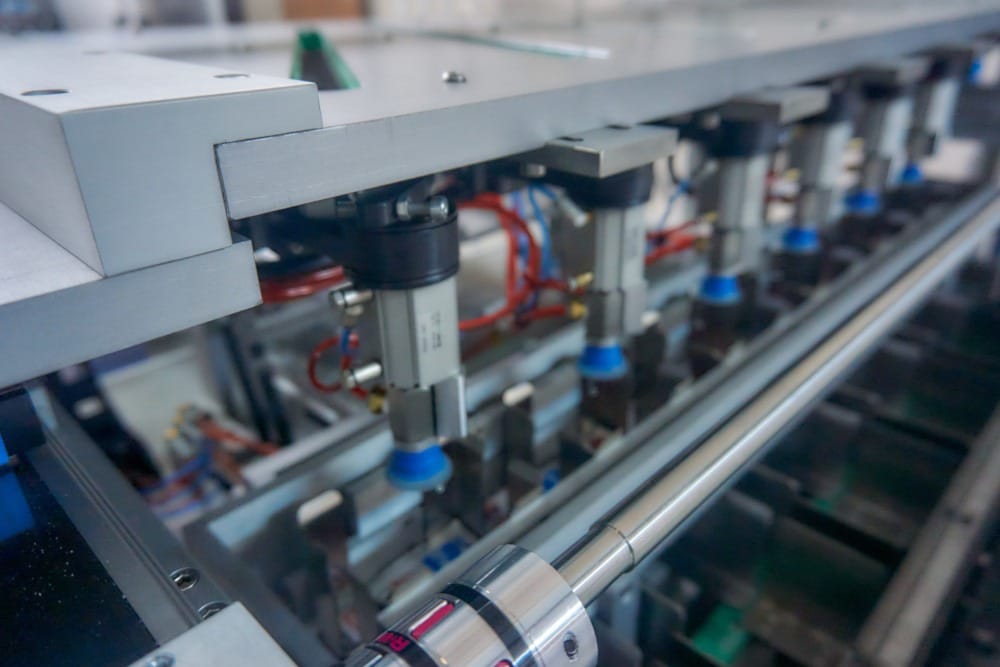

Unique extended life knife design

All motions fully synchronized with the speed

Absence of sachet burning when stopped

Easy and precise sealing pressure adjustment

On-line expiry date printing possibility

Bespoke sachet shapes

Vertical perforation

Horizontal perforation

Tear notch

User-friendly controls

Worldwide branded components

Spare parts catalogue

10 years plc & HMI software warranty

I/O test manual facility

Adjustable stacking amount on HMI

In-line working layout with flow wrapper

No Product-No Bag functionality on the flow wrapper

What can I pack?

4 Side Sealed Sachet

Flow wrapper – Horizontal Form Fill Seal

How fast I am?

Sachet machine: 60 cycle

Flow wrapper: 120 cycle

Technical details

Min. pack width : 40mm.

Max. pack width: 150mm.

Min. pack length: 50mm.

Max. pack length: 180mm.

Max. roll width : 1200mm.

Energy consumption : 5,5 kW/h

Air pressure : 6-8 Bar

Air consumption : 550 liter/min.

Electricity : 3P+N+PE 380 VAC/420VAC

Weight: 2500kg

* Above information can vary according to product type, project details and special occasions.